ASML Holding N.V. (NASDAQ:AS:ASML) is one of the most pivotal companies in the global technology ecosystem. As a leading semiconductor equipment manufacturer, its cutting-edge lithography systems are essential for producing the chips that power everything from smartphones and AI systems to advanced vehicles and IoT devices. Holding a near-monopoly in Extreme Ultraviolet (EUV) lithography, ASML is the sole supplier of EUV machines, which are critical for producing the most advanced semiconductors. This unique technology, which enables mass production of EUV chips, is indispensable for the growth of the global AI data center segment and the broader semiconductor industry.

This article delves into ASML's unrivaled leadership in lithography technology, financials, competitive positioning, and its long-term growth potential for investors seeking to capitalize on the digital age.

The Lithography MonopolyIn industries where giants like Microsoft (NASDAQ:MSFT), Google (NASDAQ:GOOGL) (NASDAQ:GOOG) (NASDAQ:GOOGL) and Amazon (NASDAQ:AMZN) compete for dominance in AI software and cloud infrastructure, or where Nvidia (NASDAQ:NVDA) and AMD (NASDAQ:AMD) challenge each other in chip design, ASML operates in a different league. Its closest competitors, Nikon and Canon, primarily provide complementary equipment rather than direct rivalry. ASML's dominance in the semiconductor lithography market is unparalleled.

At the core of this dominance lies its EUV lithography systems, which has become the cornerstone of advanced semiconductor manufacturing. EUV tools allow chipmakers to print smaller and more complex patterns on silicon wafers, enabling the production of powerful chips that drive AI, 5G networks, self-driving cars, and cutting-edge consumer electronics.

The primary advantage of EUV lies in its precision and efficiency. By using light with an extremely short wavelength (13.5 nm), EUV technology makes it possible to manufacture chips at 3nm, 2nm, and beyond. This allows billions of transistors to be packed onto a single chip, an essential development as the semiconductor industry pushes the boundaries of Moore's Law. Compared to older methods like Deep Ultraviolet (DUV), which often require multiple patterning to achieve similar results, EUV simplifies the process. Multiple patterning, which involves multiple exposures and etching steps, increases costs, complexity, and defect risk. EUV eliminates these issues, making it the preferred choice for cutting-edge semiconductor fabrication.

ASML has translated this technological edge into a near-total monopoly in lithography, with no competitors able to match its technological capabilities. This dominance extends to DUV lithography, where ASML has a substantial market share as well. According to industry estimates, Industry estimates suggest ASML controls over 90% of the global market for lithography tools, and it is the sole supplier of EUV systems. While Nikon and Canon remain competitive in legacy technologies like KrF (Krypton Fluoride) and I-line lithography, these systems are suitable for simpler, older chips and cannot compete in the high-performance segment where EUV thrives.

ASML's success is closely tied to its key customers, which include some of the largest semiconductor manufacturers in the world. TSMC (NYSE:TSM), the global leader in contract chip manufacturing, is ASML's most significant customer, relying heavily on EUV systems to produce advanced logic chips for tech giants like Apple (NASDAQ:AAPL), NVIDIA, and AMD. Similarly, Samsung (KS:005930) and Intel (NASDAQ:INTC) are critical to ASML's revenue streams, as both companies use EUV for advanced logic and memory production. Samsung uses EUV not only for its logic chips but also for DRAM and NAND memory production, while Intel employs EUV to regain competitiveness in its processor business.

Despite ASML's robust market position, analysts forecast a revenue decline in 2025, however this isn't due to ASML losing market share or competitive edge. Instead, the downturn reflects challenges faced by its key customers, such as Intel and Samsung. Intel has struggled to keep up with TSMC and AMD, leading to underutilization of its EUV capacity. Mounting losses and shrinking sales have also delayed its planned factory expansions in Europe.

Similarly, Samsung's memory business has been hit by cyclical downturns in the DRAM and NAND markets, forcing the company to scale back its capital expenditures on lithography equipment. Adding to these challenges, Samsung postponed deliveries of ASML's EUV machines for its $17 billion factory in Taylor City, Texas, citing difficulties in securing customers for the project. Originally slated to begin production in 2024, the timeline has now been pushed to 2026 or beyond, further affecting ASML's shipments.

These factors are external to ASML and do not diminish its technological leadership or the reliance of its customers on its cutting-edge tools.

Indirect Competition

Even with its dominance, ASML faces indirect competition from alternative methods that aim to reduce reliance on its EUV tools. One such method is multiple patterning, which extends the capabilities of DUV lithography to produce chips at smaller nodes. Multiple patterning allows manufacturers to achieve finer resolutions by using multiple exposures and etching steps. But there's a reason EUV is quickly replacing multiple patterning, it is incredibly complex, driving up production costs and time while increasing the risk of defects. While effective in its time, multiple patterning is now viewed as an expensive and complex workaround. It significantly increases production costs, slows down throughput, and raises the risk of defects, all factors that EUV technology directly addresses.Another alternative gaining traction is chiplet architectures, where chips are broken into smaller, modular pieces that are later reassembled. This approach reduces the need for advanced lithography for the entire chip, allowing manufacturers to mix and match older and newer technologies. For example, AMD's EPYC processors rely on chiplets for scalability and performance. However, even in this setup, EUV remains essential for producing the most advanced logic components within the chip.

Similarly, advanced packaging technologies, such as 3D stacking and 2.5D interposers, offer ways to improve chip performance by stacking or combining chips rather than shrinking them. These methods are particularly useful for extending the life of older nodes, but they cannot replace the need for EUV lithography, which remains indispensable for creating the underlying components.

The common thread among these alternatives is that they complement, rather than compete directly with, EUV. None of these methods match the precision, scalability, or efficiency of EUV, reinforcing ASML's critical role in the semiconductor value chain.

ChinaAs one of the largest and fastest-growing semiconductors markets, China has long been a major revenue driver for the company. However, geopolitical constraints, particularly those tied to export restrictions on EUV systems, complicate this relationship.

ASML is restricted from selling EUV tools to China under policies enforced by the Dutch government under pressure from the United States. These restrictions aim to curb China's access to advanced chipmaking technology and limit its ability to compete directly with global giants like TSMC and Samsung. Despite this, ASML can still sell DUV systems, which are widely used for mature and mid-tier chip manufacturing. This has allowed ASML to maintain a strong presence in China, where demand for DUV technology remains robust across consumer electronics, automotive systems, and industrial devices

To address these geopolitical challenges, ASML plans to reduce its reliance on China. The company has announced that by 2025, China's share of its total revenue will fall to 20%, returning to historical levels. This represents a significant drop from recent years, where China accounted for a larger share of ASML's sales. However, the shift poses financial hurdles. China has historically been a high-margin market for ASML, thanks to its focus on mature chip technologies. As ASML scales back its China operations, it faces a revenue gap of 8.7 billion to 10.2 billion, which must be filled to meet its 2025 revenue target of 30 billion to 35 billion ($32.5 to $38 billions).

ASML plans to offset the shortfall by focusing on its 3800E system, the latest iteration of its EUV technology. Designed for AI and advanced computing applications, the 3800E offers better performance and aligns with the growing demand for cutting-edge chips. Additionally, ASML is expanding its higher-margin service business, which provides stable revenue through maintenance and upgrades of its installed base.

Despite these efforts, the transition comes with risks. ASML's success will depend on customers like TSMC and Intel ramping up their production of advanced chips, particularly for AI applications, which require the company's most sophisticated machines.

The recent sell-offASML has faced significant headwinds recently, shedding over 60 billion ($65 billion) in market capitalization since it reported third-quarter 2024 bookings that were less than half of what analysts had expected. Specifically, bookings fell to 2.63 billion, well below the 5.39 billion ($5.84 billion). While the company's existing 36 billion order backlog offers some cushion, slower market conditions mean the company will ship fewer than 50 EUV systems in 2025. This reduction puts pressure on ASML's profit margins, which are now forecasted to range between 51% and 53%, down from earlier expectations of 54% to 56%.

ASML's management has also lowered its 2025 revenue guidance, projecting sales 30 billion to 35 billion ($32.5 to $38 billions), down from the previous estimate of up to 40 billion ($43 billion). This revision underscores the challenges the company faces, particularly in weaker demand for logic chips, a slower-than-expected ramp-up in memory production, and declining sales of immersion systems in China.

Despite these short-term challenges, ASML remains optimistic about the future. During its 2024 Investor Day, management reiterated its bullish long-term outlook, projecting annual revenue of 44 billion to 60 billion ($47.5 to $65 billions) by 2030, with gross margins climbing to between 56% and 60%. This optimism stems from the anticipated growth in several key end markets, including AI, 5G, and high-performance computing. ASML believes AI, in particular, represents a transformative opportunity, driving demand for more powerful chips and further entrenching ASML's role in the semiconductor value chain.

The semiconductor industry itself is forecasted to grow to over $1 trillion in annual sales by 2030, with a compound annual growth rate (CAGR) of approximately 9% between 2025 and 2030. Statista, for example, expects an annual growth rate of 10.06%, which aligns closely with ASML's projected CAGR of 11%, slightly above broader industry estimates.

ValuationFollowing the sharp drop in its stock price after the Q3 earnings announcement, ASML's shares have shown signs of stabilization. In my view, this dip may present a compelling opportunity for long-term investors.

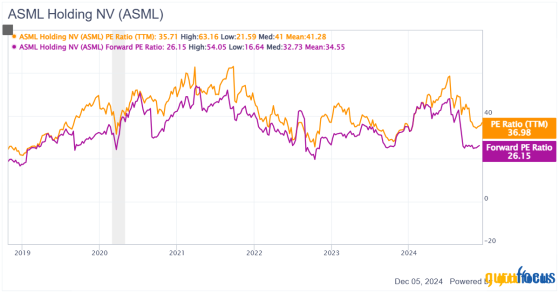

ASML's price-to-earnings (P/E) ratio currently stands at 37x, slightly below the company's historical P/E average of 42x, with a forward P/E of 26x. While these multiples reflect the challenges ASML faces in the near term, they remain reasonable for a company with a monopoly in EUV lithography and a strong growth trajectory over the next decade.

However, probably the best way to analyze ASML price is by using other multiples incorporating management estimates for 2025 and 2030.

I used a valuation approach that involves considering ASML's 2030 revenue projections. Using management's estimates of 44 to 60 billion with a gross margin of 56% to 60%. Assuming no significant dilution in shares and applying a price-to-gross profit multiple of 22x, which reflects ASML's five-year average, my analysis points to a target price by 2030 ranging between 1,426 and 1,944 per share. Discounting these to 2024 using a discount rate of 8.30%, I arrive at an implied share price of 885 to 1,208, with an average of 1,047, a 65% upside from the current price of 658.

Source: Author

ConclusionASML's dominant position in lithography, especially its EUV technology, secures its place at the heart of the global semiconductor industry. The recent sell-off reflects short-term challenges, from weakened customer demand to geopolitical tensions. However, I believe these are temporary setbacks that do not undermine ASML's unparalleled technological edge or its importance in the semiconductor value chain.

Looking ahead, ASML's ability to execute its long-term strategy, especially in AI-driven markets, will be key. Management will need to reassure investors every quarter over the next few years that its long-term guidance remains on track.

This content was originally published on Gurufocus.com

Which stock should you buy in your very next trade?

With valuations skyrocketing in 2024, many investors are uneasy putting more money into stocks. Unsure where to invest next? Get access to our proven portfolios and discover high-potential opportunities.

In 2024 alone, ProPicks AI identified 2 stocks that surged over 150%, 4 additional stocks that leaped over 30%, and 3 more that climbed over 25%. That's an impressive track record.

With portfolios tailored for Dow stocks, S&P stocks, Tech stocks, and Mid Cap stocks, you can explore various wealth-building strategies.